These lightweight concrete houses offer endless design possibilities to suitall your requirements

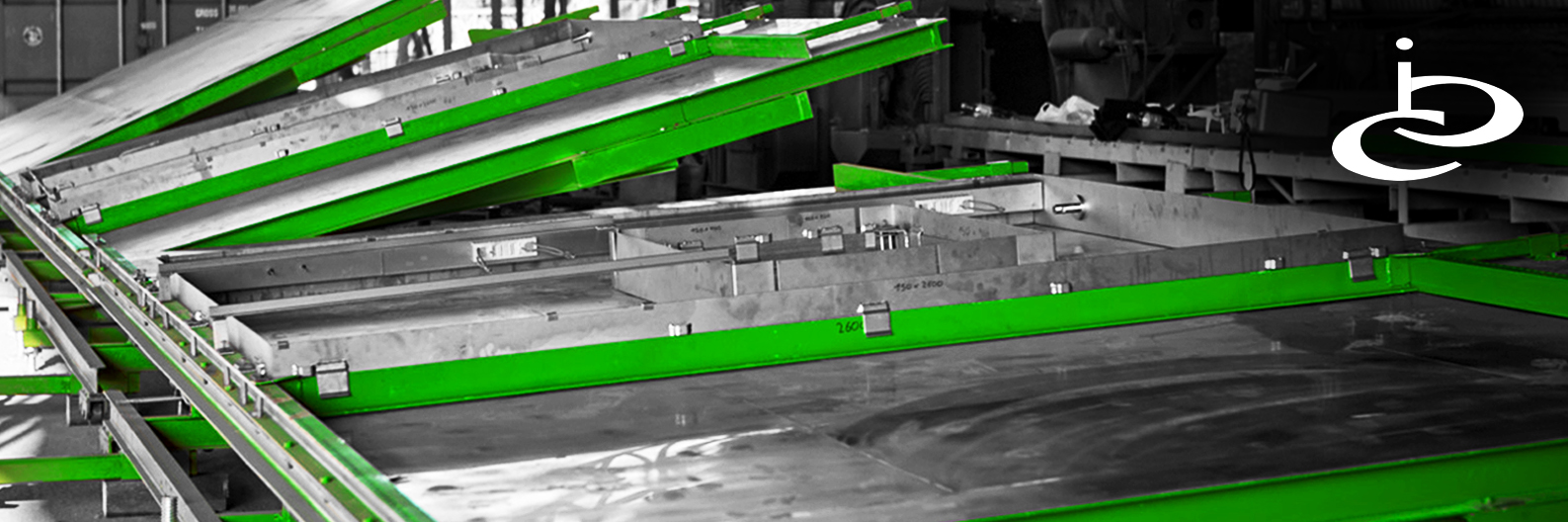

The flexmobox container is equipped with an adjustable table form which can be used to make lightweight concrete elements to your own specifications, including floors, ceilings and walls with movable block-outs for doors and windows. You can use trusted standard designs or implement your own plans.

There are no limits to the size and architectural design of the houses that can be built using this modular construction system. Both one-storey and multi-storey buildings can be constructed, including single-family houses, apartment buildings, schools, hospitals and other public buildings.

Operating the table form and assembling the finished elements are simple procedures and easy to learn. After instruction and a relatively short training period, local personnel can carry out most of the tasks all by themselves.

Operating the table form and assembling the finished elements are simple procedures and easy to learn. After instruction and a relatively short training period, local personnel can carry out most of the tasks all by themselves.

Anywhere

The mobile factory in container format produces lightweight concrete precast elements for houses – individually designed to suit your specific requirements.

Inexpensive

The innovative concrete mix allows lightweight concrete to be made with very little steel and almost exclusively from local raw materials.

Simple

The modular construction system is suitable for one-story and multi-story buildings like single-family houses, apartment buildings, schools, hospitals and so on.

Fast

Trained local staff can produce elements for 4 to 10 houses per month using only one Flexmobox.

Versatility

The flexmobox system is suitable for all types of buildings, from small houses to large multi-storey hospitals. The system is so flexible that you can install it wherever the need is greatest.

Regionalism

The small-scale manufacturing units in container form can be used in areas where transport infrastructure is poor or after disasters. The use of almost entirely local materials means that even the smallest projects can be economically feasible.

Affordability

Because the construction method uses hardly any steel, considerable savings on material and transport costs may be made – and if the steel has to be imported, this saves valuable foreign currency too.

Sustainability

Local workers are trained and employed, giving a significant boost to the local economy that normally lasts beyond the end of the construction project.

With flexmobox, at last there is a promising solution to the acute global housing shortage!